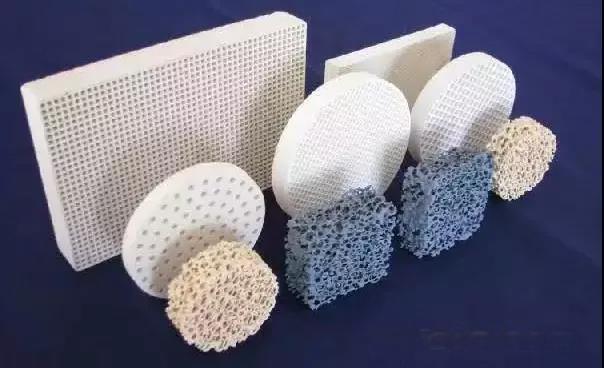

Surgical Sponge Dressing

Surgical Sponge Dressing

Oct .14.2024

The main material of surgical sponge dressing is medical PVA sponge. PVA medical grade macroporous sponge has excellent liquid absorption function, high comfort level, high strength, and soft appearance when touched with human body, which is widely used i

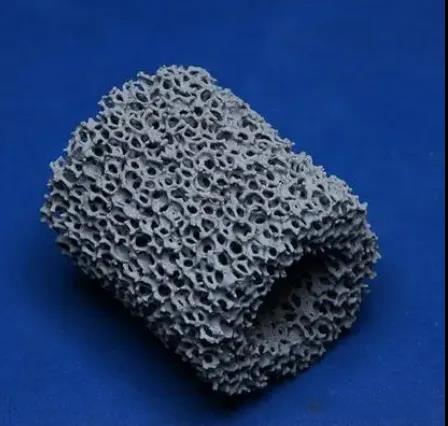

What is Cellulose Sponge and its Advantages

What is Cellulose Sponge and its Advantages

Oct .12.2024

Cellulose sponges are made from cellulose fibers and are environmentally friendly and biodegradable. They don't leave any residue on surfaces, making them perfect for cleaning delicate items.

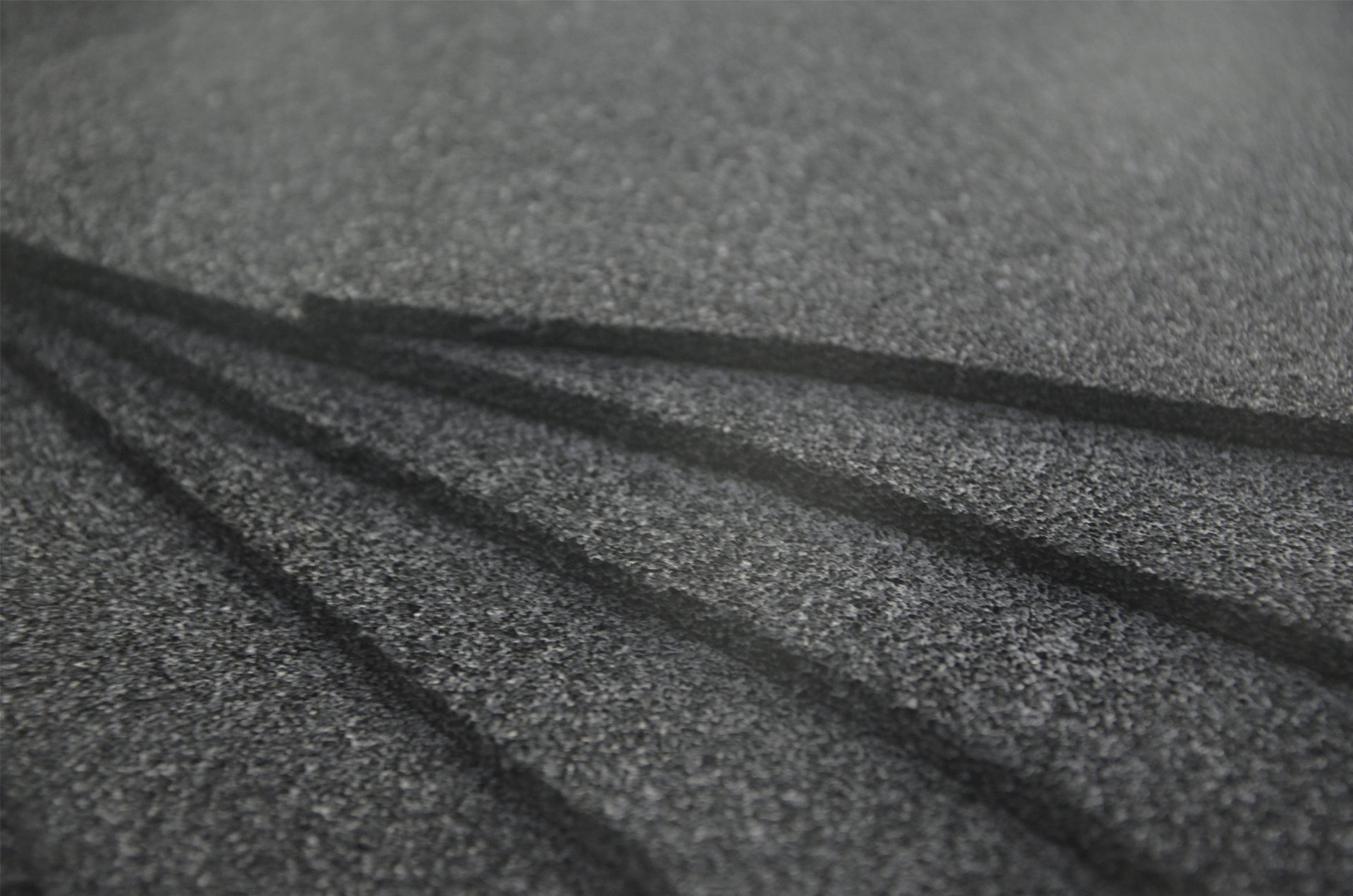

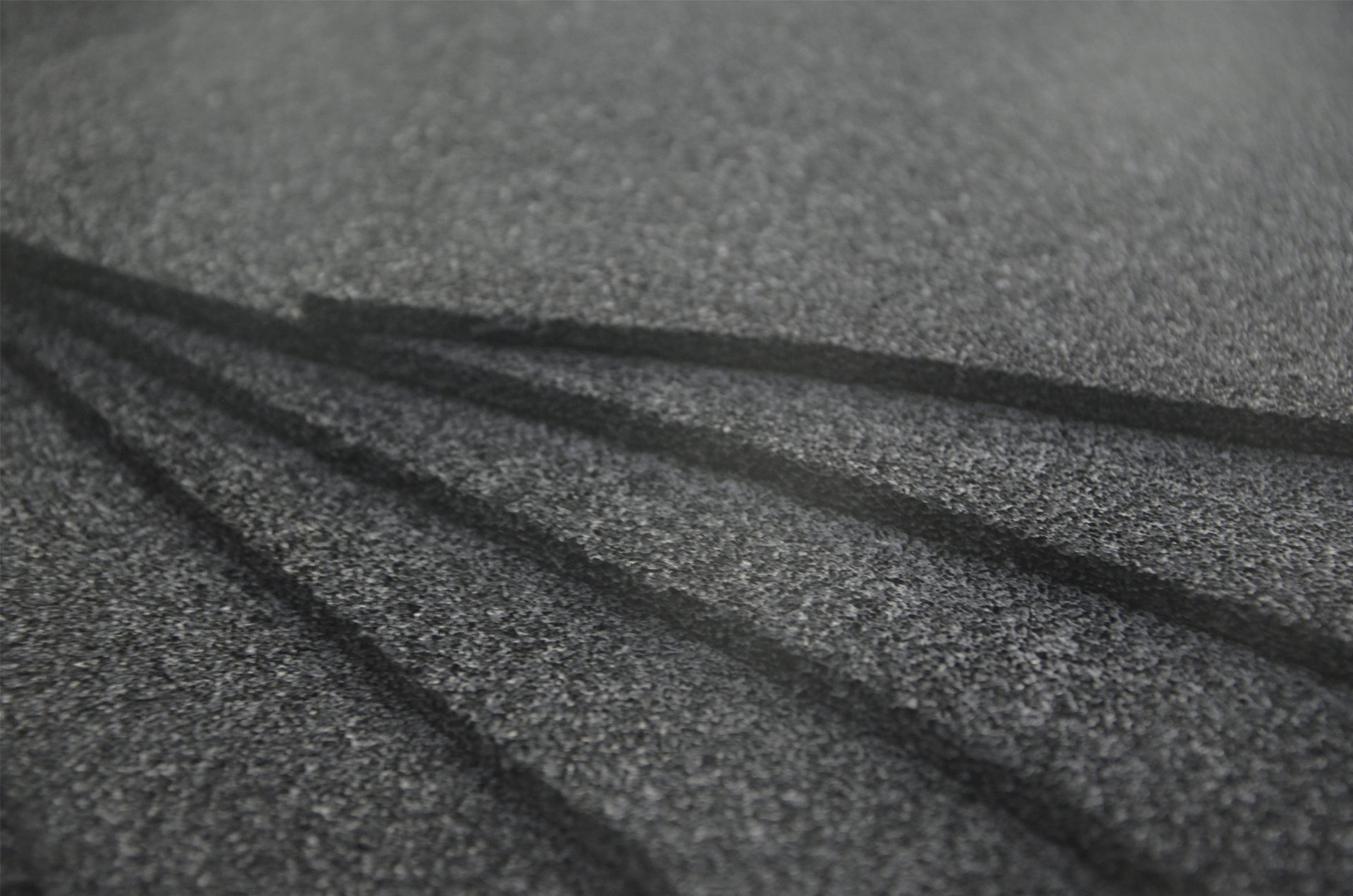

The Application of EPDM Foam

The Application of EPDM Foam

Oct .10.2024

EPDM Foam is a multifunctional synthetic rubber material with excellent physical and chemical properties, which is widely used in many different application fields and is one of the indispensable materials in modern industry.

Gel Memory Foam for Mattress

Gel Memory Foam for Mattress

Oct .09.2024

Gel memory foam are actually memory foam infused with gel microbeads. Adding gel microbeads to the memory foam helps create a more breathable foam, which helps regulate body temperature during sleep.

Surgical Sponge Dressing

Surgical Sponge Dressing

What is Cellulose Sponge and its Advantages

What is Cellulose Sponge and its Advantages

The Application of EPDM Foam

The Application of EPDM Foam

Gel Memory Foam for Mattress

Gel Memory Foam for Mattress