Introduction of EPDM Foam Production Process

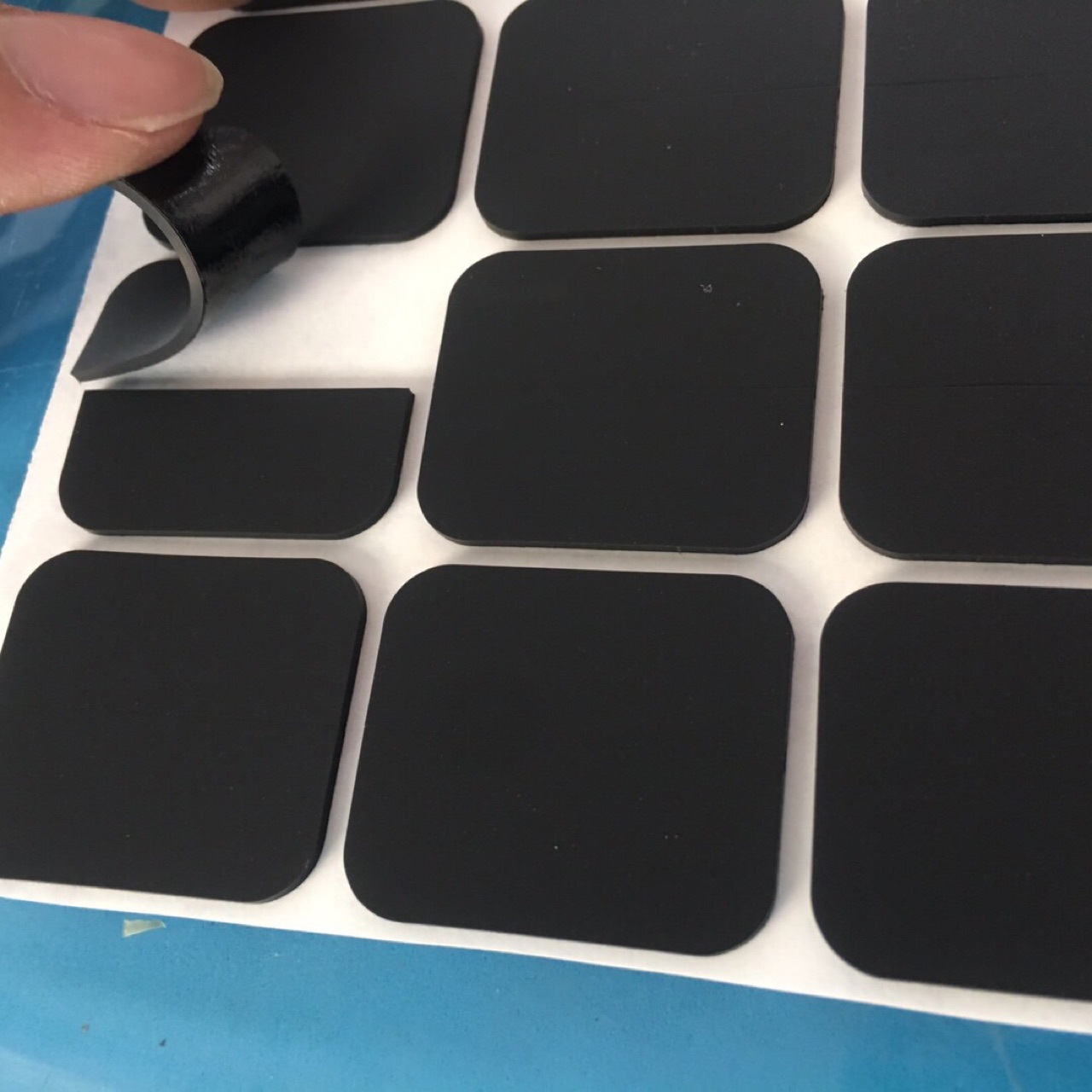

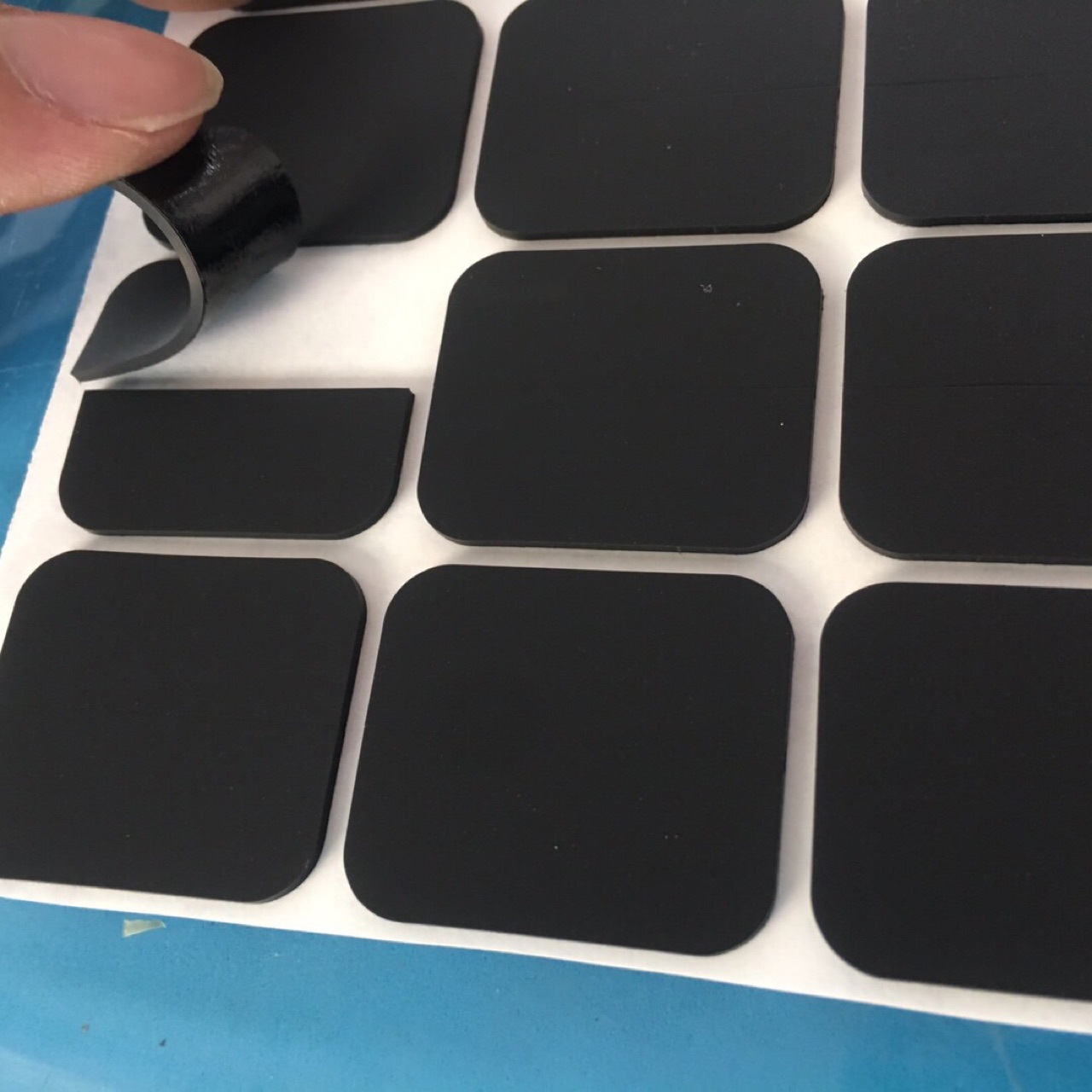

EPDM foam is carefully controlled by rolling and cooling of raw materials, aging and resting, and then extrusion with high density and aging and resting to mold vulcanization, foaming, aging and safe periodic storage process, ensuring the quality of finished EPDM closed cell foam raw bed. High strength impact resistance; Absorbing vibration to reduce vibration and noise; The role of heat insulation. The foam bed is cut and processed to provide sheets of different thickness from 1mm to 60mm. The original bed can be used to produce functional products with different needs through various processes such as coating, backing glue, scuttling, die-cutting and compounding.

Characteristic Analysis of EPDM Foam

Characteristic Analysis of EPDM Foam

1. Close

d cell material density 55-750kg/m³, wide range, strong selectivity

2. Excellent aging resistance, weather resistance (light, heat and oxygen), excellent ozone resistance; Temperature resistance (-40℃ to 150℃)

3. Low thermal conductivity (3.2), good heat insulation and insulation

4. High impact strength, good shock absorption and shock absorption performance

5. Good insulation performance

6. Wide range of hardness, can meet the needs of 5 degrees to 70 degrees (Shore C)

7. Low odor, low VOC, TVOC standard, more in line with automotive industry standards

8. The material is more environmentally friendly, and the environmental protection grade is diversified: low halogen series, low sulfur series, low ammonia series, halogen-free series, sulfur free series, ammonia free series.

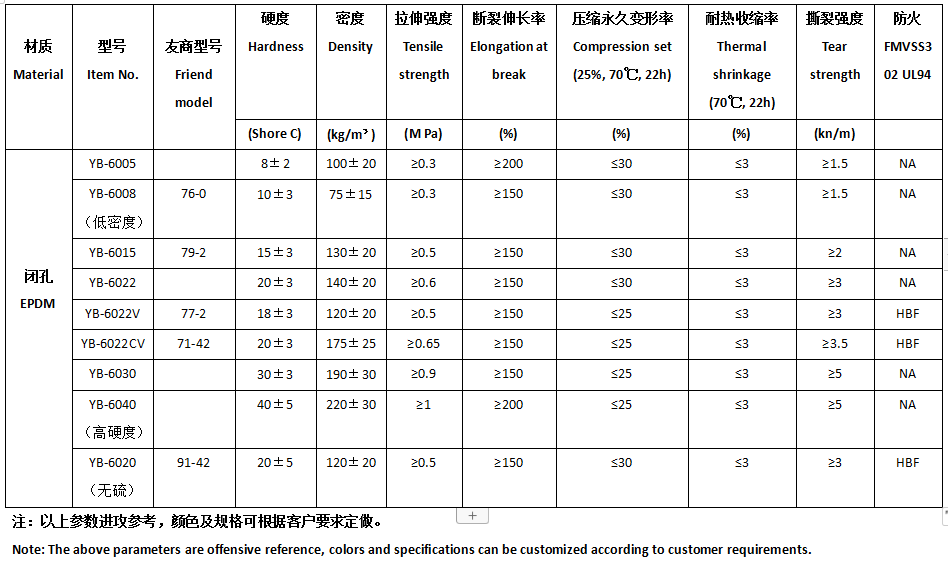

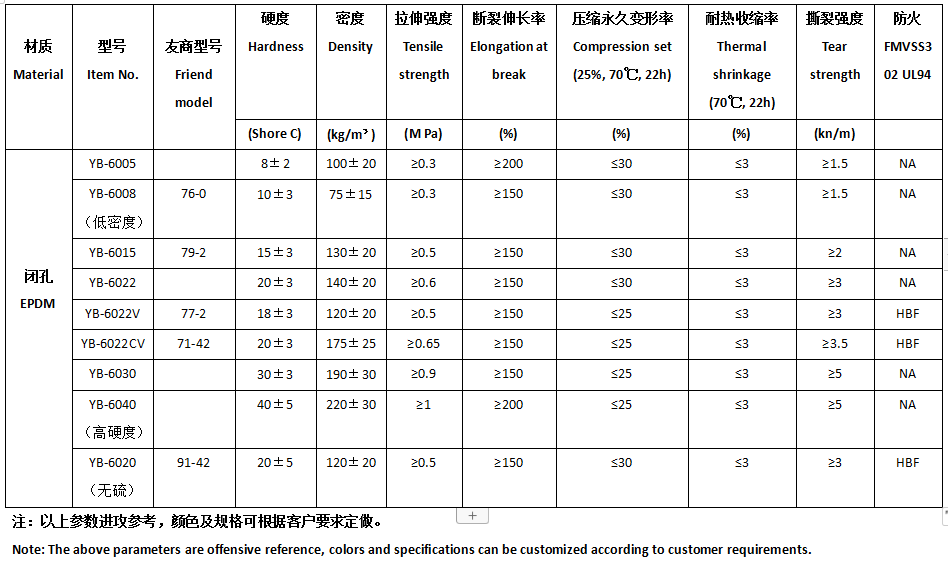

Data Sheets of EPDM Foam

Application of EPDM Foam

1. Automotive industry: light baffle, door mirror, taillight, door, trunk seal, engine shock proof material

2. Household appliances: sealing materials for refrigerators, refrigerating devices, air conditioners and vending machines

3. Packaging materials: cushioning and shock-proof materials for precision instruments and medical equipment transportation

4. Building materials: residential sound wall materials, decoration panels, sealing materials for house doors and Windows.